STARTING (Continued)

ÁÁ ELECTRIC STARTER:

A. Move choke lever (see Figure 3 or 4) to “FULL CHOKE POSITION”.

NOTE: IF RESTARTING A WARM ENGINE AFTER A SHORT

SHUTDOWN, MOVE CHOKE LEVER TO “NO CHOKE

POSITION”.

B. Move equipment control (see manufacturer’s instructions) or engine

control to “START”.

C. Push starter button or turn ignition switch key (see equipment

manufacturer’s instructions) to crank engine.

D. Crank engine until it fires. When it starts, release starter button or

ignition switch key and move choke lever to “1/2 CHOKE” until engine

runs smoothly and then to “NO CHOKE POSITION”.

If engine falters, move choke lever to “1/2 CHOKE” until engine runs

smoothly and then to “NO CHOKE POSITION”.

NOTE: If engine fires, but does not continue to run, move choke lever

to “NO CHOKE POSITION’’ and crank engine until it starts.

NOTE: If engine again fires, but does not continue to run, move

choke lever to “FULL CHOKE” and repeat instructions B, C

and D until engine starts.

STOPPING

ÀÀ Move equipment control or any ignition stop switch on engine to “STOP” or

“OFF” (see equipment manufacturer’s instructions).

ÁÁ Push stop switch (if so equipped see Figure 1) located next to spark plug

on engine against spark plug and hold it in this position until engine is

completely stopped.

ÂÂ AFTER ENGINE IS STOPPED:

A. Close fuel valve (if so equipped).

B. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

C. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO “OFF”

POSITION AND REMOVE KEY FROM SWITCH, THIS WILL REDUCE

THE POSSIBILITY OF UNAUTHORIZED STARTING OF ENGINE

WHILE EQUIPMENT IS NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL FUMES

MAY REACH AN OPEN FLAME, SPARK OR PILOT LIGHT AS ON

A FURNACE, WATER HEATER, CLOTHES DRYER OR OTHER

GAS APPLIANCE.

MAINTENANCE

WARNING: TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150

0

F (65

0

C). AVOID THESE AREAS.

ÀÀ OIL LEVEL:

Check oil level every five (5) operating hours and before each use. See

“FILL OIL SUMP OR CHECK OIL LEVEL’’ on Page 2.

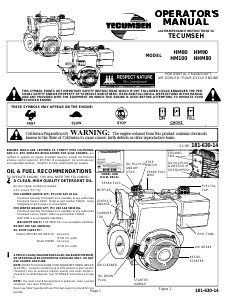

ÁÁ CHANGE OIL (see Figure 1):

Change oil after first two (2) operating hours and every 25 operating hours

thereafter, more often if operated in extremely dusty or dirty conditions.

Change oil while engine is still warm from recent running.

A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

B. Clean area around oil drain plug (see Figure 1).

C. Position equipment so engine oil drain plug is lowest point on engine.

D. Remove oil drain plug and oil fill plug to drain oil.

E. Install oil drain plug and tighten securely.

F. Fill oil sump with recommended oil. See “OIL & FUEL

RECOMMENDATIONS’’ on Pages 1 and 2 and “FILL OIL SUMP OR

CHECK OIL LEVEL” on Page 2.

G. Install oil fill plug and tighten securely.

H. Wipe up any spilled oil.

MAINTENANCE (Continued)

ÂÂ COOLING SYSTEM (see Figure 1 and Figure 5):

IMPORTANT: Frequently remove grass clippings, dirt and debris

from cooling fins, air intake screen and levers and linkage. This

will help ensure adequate cooling and correct engine speed.

Figure 6

Figure 5

COOLING

FINS

AIR INTAKE SCREEN

(IF SO EQUIPPED)

PORCELAIN

.030 GAP

ELECTRODES

ÃÃ SPARK PLUG (see Figure 6):

This spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations. This engine complies with

all current Australian and New Zealand limitations regarding electromagnetic

interference. Check spark plug yearly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or porcelain is

cracked. For replacement use Champion RJ-17LM only.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at .030 if

necessary.

E. Install spark plug, tighten securely.

ÄÄ AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE

AIR CLEANER INSTALLED ON ENGINE.

A. TO SERVICE FILTER(S) (see Figure 7):

1. FOAM FILTER:

Clean and re-oil every three (3) months or every 25 operating

hours. Clean and re-oil daily if used in extremely dusty conditions.

NOTE: DO NOT OIL FOAM FILTER ON AIR CLEANER "A".

a. Wash in water and detergent solution and squeeze (don’t

twist) until all dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don’t twist) until completely

dry.

d. Saturate with engine oil and squeeze (don’t twist) to distribute

oil and remove excess oil.

2. PAPER FILTER:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every 100 operating hours, more often if

used in extremely dusty conditions. Replacement filters are

available at any Authorized Tecumseh Service Outlet.

Join the conversation about this product

Here you can share what you think about the Tecumseh HM100 Engine. If you have a question, first carefully read the manual. Requesting a manual can be done by using our contact form.