INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la

mort ou de sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce

produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil

motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs et propriétaires

avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être conservé dans un

endroit sûr.

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and

understand this manual BEFORE operating the power tool. Please keep this manual

available for other users and owners before they use the power tool. This manual should

be stored in safe place.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y

comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde este manual

para que puedan leerlo otras personas antes de utilizar la herramienta eléctrica. Este

manual debe ser guardado en un lugar seguro.

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in the Instruction Manual

before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous situation

before it occurs, and by observing appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and in the sections which

contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on the

power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in death or serious injury.

CAUTION indicates a potentially hazardous situations which, if not avoided, may result in minor or moderate injury,

or may cause machine damage.

NOTE emphasizes essential information.

SAFETY

GENERAL SAFETY RULES – FOR ALL BATTERY OPERATED TOOLS

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1. Work Area

(1) Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

(2) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids,

gases, or dust. Power tools create sparks which may ignite the dust of fumes.

(3)

Keep bystanders, children and visitors away while operating a power tool. Distractions can cause you to lose control.

2. Electrical Safety

(1) A battery operated tool with integral batteries or a separate battery pack must be recharged only with

the specified charger for the battery. A charger that may be suitable for one type of battery may create a

risk of fire when used with another battery.

(2) Use battery operated tool only with specifically designed battery pack. Use of any other batteries may

create a risk of fire.

3. Personal Safety

(1) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

(2) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

(3) Avoid accidental starting. Be sure switch is off position before inserting battery. Carrying tools with your

finger on the switch or inserting the battery pack into a tool with the switch on invites accidents.

(4) Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

(5) Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enable better

control of the tool in unexpected situations.

(6) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

4. Tool Use and Care

(1) Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may lead to loss of control.

(2) Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer

at the rate for which it is designed.

(3) Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

(4) Disconnect battery pack from tool or place the switch in the locked or off position before making any

adjustments, changing accessories, or storing the tools. Such preventive safety measures reduce the risk

of starting the tool accidentally.

(5) Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of

untrained users.

(6) When battery pack is not in use, keep it away from other metal objects like: paper clips, coins, keys, nails,

screws, or other small metal objects that can make a connection from one terminal to another. Shorting

the battery terminals together may cause sparks, burns, or a fire.

(7) Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting

edges are less likely to bind and are easier to control.

(8) Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may

affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by

poorly maintained tools.

(9) Use only accessories that are recommended by the manufacturer for your model. Accessories that may

be suitable for one tool, may become hazardous when used on another tool.

5. Service

(1) Tool service must be performed only by qualified repair personnel. Service or maintenance performed by

unqualified personnel could result in a risk of injury.

(2) When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or failure to follow Maintenance Instruction may create

a risk of electric shock or injury.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

●

Lead from lead-based paints,

●

Crystalline silica from bricks and cement and other masonry products, and

●

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

SPECIFIC SAFETY RULES

1.

Hold tools by insulated gripping surfaces when performing an operation where the cutting tool may contact

hidden wiring. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

2. Never touch moving parts.

Never place your hands, fingers or other body parts near the tool’s moving parts.

3. Never operate without all guards in place.

Never operate this tool without all guards or safety features in place and in proper working order. If maintenance

or servicing requires the removal of a guard or safety feature, be sure to replace the guard or safety feature

before resuming operation of the tool.

4. Use right tool.

Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended —for example— don’t use circular saw for cutting tree limbs or logs.

5. Never use a power tool for applications other than those specified.

Never use a power tool for applications other than those specified in the Instruction Manual.

6. Handle tool correctly.

Operate the tool according to the instructions provided herein. Do not drop or throw the tool. Never allow the

tool to be operated by children, individuals unfamiliar with its operation or unauthorized personnel.

7. Definitions for symbols

V ................. volts n

o

.................... no load speed

---

— ................ direct current ---/min ............. revolutions or reciprocation per minute

8. Keep all screws, bolts and covers tightly in place.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

9. Do not use power tools if the plastic housing or handle is cracked.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not be used until repaired.

10. Blades and accessories must be securely mounted to the tool.

Prevent potential injuries to yourself or others. Blades, cutting implements and accessories which have been

mounted to the tool should be secure and tight.

11. Never use a tool which is defective or operating abnormally.

If the tool appears to be operating unusually, making strange noises, or otherwise appears defective, stop

using it immediately and arrange for repairs by a Hitachi authorized service center.

12. Carefully handle power tools.

Should a power tool be dropped or struck against hard materials inadvertently, it may be deformed, cracked, or damaged.

13. Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner, benzine, carbon tetrachloride and alcohol may damage and crack plastic

parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry thoroughly.

IMPORTANT SAFETY INSTRUCTIONS FOR USE OF THE CORDLESS IMPACT DRIVER / WRENCH

WARNING:

Death or serious bodily injury could result from improper or unsafe use of the cordless impact driver. To avoid

these risks, follow these basic safety instructions:

1. Never use this tool handle for any application other than those in this manual.

2. Never place hands or other body parts near the drill bit or chuck during operation.

Hold the impact driver by its handle only.

3. When working in high places, always make sure that there is no one below before starting to work.

4. Always wear eye and ear protection when you work.

5.

Always install the driver bit securely. A loose bit is dangerous because it can come loose while you are working. (Impact driver)

6. Always use the driver bit that matches the screw size. (Impact driver)

7.

Always have the screw you are screwing in and this impact driver in a straight line. Working with this impact driver at an

angle to the screw can damage the screw head and will not give the prescribed tightening torque. (Impact driver)

8. Confirm whether the socket has any crack in it. (Impact wrench)

9. Attach the hex. socket securely onto the anvil. If the hex. socket is insufficiently secured, it may drop out and

cause an accident. For hex. socket attachment refer to “OPERATION”.

10. Confirm the tightening torque by a torque wrench before use in order to ascertain the correct tightening torque

to be used. (Impact wrench)

11. If a universal joint is used, be sure not to operate the unit in a no-load condition. Operating in this condition is

dangerous. When the socket section spins around it may cause injury to hands or bodies, or the resulting

intense vibration may cause the user to drop the tool. (Impact wrench)

12. Be careful that foreign matters do not block the holes located on both sides of the handle. Also do not close the

holes with a tape. The holes act an important role. (Impact wrench)

IMPORTANT SAFETY INSTRUCTIONS FOR BATTERY CHARGER

1. This manual contains important safety and operating instructions for battery charger Model UC14YFA or

UC24YFA or UC18YG.

2. Before using battery charger, read all instructions and cautionary markings on (1) battery charger, (2) battery,

and (3) product using battery.

3. To reduce risk of injury, charge HITACHI rechargeable battery type EB7, EB9, EB12, EB14, EB18 series. Other

type of batteries may burst causing personal injury and damage.

4. Do not expose battery charger to rain or snow.

5. Use of an attachment not recommended or sold by the battery charger manufacturer may result in a risk of fire,

electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and cord, pull by plug when disconnecting battery charger.

7.

Make sure cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

8. An extension cord should not be used unless absolutely necessary. Use of improper extension cord could

result in a risk of fire and electric shock.

If extension cord must be used make sure:

a. That blades of extension cord are the same number, size, and shape as those of plug on battery charger;

b. That extension cord is properly wired and in good electrical condition; and

c. That wire size is large enough for AC ampere rating of battery charger as specified in Table 1.

Table 1

RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS FOR BATTERY CHARGERS

AC Input Rating Amperes* AWG Size of Cord

Equal to or but less Length of Cord, Feet (Meter)

greater than than 25 (7.5) 50 (15) 100 (30) 150 (45)

0 2 18 18 18 16

2 3 18 18 16 14

3 4 18 18 16 14

*If the input rating of a battery charger is given in watts rather than in amperes, the corresponding ampere

rating is to be determined by dividing the wattage rating by the voltage rating–for example:

1,250 watts

125 volts

=

10

amperes

9. Do not operate battery charger with damaged cord or plug – replace them immediately.

10. Do not operate battery charger if it has received a sharp blow, been dropped, or otherwise damaged in any

way; take it to a qualified serviceman.

11. Do not disassemble battery charger; take it to a qualified serviceman when service or repair is required. Incorrect

reassembly may result in a risk of electric shock or fire.

12. To reduce risk of electric shock, unplug charger from receptacle before attempting any maintenance or cleaning.

Removing the battery will not reduce this risk.

IMPORTANT SAFETY INSTRUCTIONS FOR USE OF THE BATTERY AND BATTERY CHARGER

You must charge the battery before you can use the cordless impact wrench. Before using the model UC14YFA or

UC24YFA or UC18YG battery charger, be sure to read all instructions and cautionary statements on it, the battery

and in this manual.

REMEMBER: USE ONLY HITACHI BATTERY TYPES EB7 SERIES, EB9 SERIES, EB12 SERIES, EB14 SERIES. EB18

SERIES. OTHER TYPES OF BATTERIES MAY BURST AND CAUSE INJURY!

Follow these instructions to avoid the risk of injury:

WARNING:

Improper use of the battery or battery charger can lead to serious injury. To avoid these injuries:

1. NEVER disassemble the battery.

2. NEVER

incinerate the battery, even if it is damaged or is completely worn out. The battery can explode in a fire.

3. NEVER short-circuit the battery.

4. NEVER insert any objects into the battery charger’s air vents. Electric shock or damage to the battery

charger may result.

5. NEVER charge outdoors. Keep the battery away from direct sunlight and use only where there is low

humidity and good ventilation.

6. NEVER charge when the temperature is below 32°F (0°C) or above 104°F (40°C).

7. NEVER connect two battery chargers together.

8. NEVER insert foreign objects into the hole for the battery or the battery charger.

9. NEVER use a booster transformer when charging.

10. NEVER use an engine generator or DC power to charge.

11. NEVER

store the battery or battery charger in places where the temperature may reach or exceed 104°F (40°C).

12. ALWAYS operate charger on standard household electrical power (120 volts). Using the charger on any

other voltage may overheat and damage the charger.

13. ALWAYS wait at least 15 minutes between charges to avoid overheating the charger.

14. ALWAYS disconnect the power cord from its receptacle when the charger is not in use.

SAVE THESE INSTRUCTIONS

FUNCTIONAL DESCRIPTION

NOTE:

The information contained in this Instruction Manual is designed to assist you in the safe operation and

maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read and understood all

safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that differ from those on

your own power tool.

SPECIFICATIONS

1. Cordless Impact Driver

Model WH9DMR WH12DMR WH14DMR WH18DMR

Voltage 9.6 V 12 V 14.4 V 18 V

No-Load speed 0 – 2600 / min

Capacity (Ordinary bolt)

M5 – M12 M6 – M14

Tightening torque 930 in-lbs 1,150 in-lbs 1,240 in-lbs 1,330 in-lbs

(Maximum) (105 N·m) (130 N·m) (140 N·m) (150 N·m)

Weight 3.1 lbs. (1.4 kg) 3.5 lbs. (1.6 kg) 3.9 lbs. (1.8 kg) 4.4 lbs. (2.0 kg)

Model UC14YFA UC24YFA UC18YG

Charging voltage 7.2 – 14.4 V 7.2 – 24 V 7.2 – 18 V

2.0 Ah 50 min. 50 min. 50 min.

Charging time 2.6 Ah 65 min. 65 min. x

3.0 Ah 70 min. 70 min. x

Weight 1.3 lbs. (0.6 kg) 1.3 lbs. (0.6 kg) 0.7 lbs. (0.3 kg)

Model WR9DMR WR12DMR WR14DMR WR18DMR

Voltage 9.6 V 12 V 14.4 V 18 V

No-Load speed 0 – 2600 / min

Capacity (Ordinary bolt)

M6 – M14 M10 – M16

Tightening torque 1,020 in-lbs 1,420 in-lbs 1,720 in-lbs 1,950 in-lbs

(Maximum) (115 N·m) (160 N·m) (195 N·m) (220 N·m)

Weight 3.1 lbs. (1.4 kg) 3.5 lbs. (1.6 kg) 3.9 lbs. (1.8 kg) 4.4 lbs. (2.0 kg)

2. Cordless Impact Wrench

3. Battery Charger

All charge times are approximate. Actual charge time may vary.

“x” Indicates that the battery pack is not compatible with that specific charger.

WR12DMR

WH12DMR

Model

Modèle

Modelo

Variable speed

Cordless Impact Driver

Visseuse à percussion à batterie

Atornillador de impacto a battería

Cordless Impact Wrench

Clé à choc à batterie

Llave de impacto a batería

WH 9DMR

•

WH 12DMR

•

WH 14DMR

•

WH 18DMR

WR 9DMR

•

WR 12DMR

•

WR 14DMR

•

WR 18DMR

English

MAINTENANCE AND INSPECTION

CAUTION:

Pull out battery before doing any inspection or maintenance.

1. Checking the condition of the bit (Impact driver)

The bits should be checked regularly. If worn or broken bits can slip or decrease the efficiency of the motor and burn it out.

Replace worn bits with new ones.

CAUTION:

If you use a driver bit of which point is worn or broken, it will be dangerous since it slips. So replace it with a new one.

2. Checking the condition of the socket (Impact wrench)

A worn or deformed hex. or a square-holed socket will not give an adequate tightness to the fitting between

the nut or anvil, consequently resulting in loss of tightening torque. Pay attention to wear of a socket holes

periodically, and replace with a new one if needed.

3. Check the Screws

Loose screws are dangerous. Regularly inspect them and make sure they are tight.

CAUTION:

Using this power tool with loosened screws is extremely dangerous.

4. Maintenance of the motor

The motor unit winding is the very “heart” of the power tool.

Exercise due care to ensure the winding does not become damaged and/or wet with oil or water.

5. Inspecting the carbon brushes (Fig. 13)

The motor employs carbon brushes which are consumable parts. Since and excessively worn carbon brush can

result in motor trouble, replace the carbon brush with new ones when it becomes worn to or near the “wear limit”

P

. In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders.

NOTE:

When replacing the carbon brush with a new one, be sure to use the Hitachi Carbon Brush Code No. 999054.

6. Replacing carbon brushes

Take out the carbon brush by first removing the brush cap and then hooking the protrusion

R

of the carbon

brush with a flat head screw driver, etc., as shown in Fig. 15.

When installing the carbon brush, choose the direction so that the nail

Q

of the carbon brush agrees with the contact

portion outside the brush tube

S

. Then push it in with a finger as illustrated in Fig. 16. Lastly, install the brush cap.

CAUTION:

●

Be absolutely sure to insert the nail of the carbon brush into the contact portion outside the brush tube. (You

can insert whichever one of the two nails provided.)

●

Caution must be exercised since any error in this operation can result in the deformed nail of the carbon brush

and may cause motor trouble at an early stage.

7. Check for Dust

Dust may be removed with a soft cloth or a cloth dampened with soapy water.

Do not use bleach, chlorine, gasoline or thinner, for they may damage the plastics.

8. Disposal of the exhausted battery

WARNING:

Do not dispose of the exhausted battery. The battery must explode if it is incinerated. The product that you

have purchased contains a rechargeable battery. The battery is recyclable. At the end of it’s useful life, under

various state and local laws, it may be illegal to dispose of this battery into the municipal waste stream.

Check with your local solid waste officials for details in your area for recycling options or proper disposal.

9. Storage

Storing in a place below 104°F (40°C) and out of the reach of children.

10. Service and repairs

All quality power tools will eventually require servicing or replacement of parts because of wear from normal

use. To assure that only authorized replacement parts will be used, all service and repairs must be performed

by a HITACHI AUTHORIZED SERVICE CENTER, ONLY.

ACCESSORIES

WARNING:

ALWAYS use Only authorized HITACHI replacement parts and accessories. NEVER use replacement parts or

accessories which are not intended for use with this tool. Contact HITACHI if you are not sure whether it is

safe to use a particular replacement part or accessory with your tool.

The use of any other attachment or accessory can be dangerous and could cause injury or mechanical damage.

NOTE:

Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES

1

Battery Charger (UC14YF2 or UC14YFA or UC18YG) ......................1

2

Plastic Case ..........................................................................................1

(For 9.6 V / 12 V Code No. 322070)

(For 14.4 V / 18 V Code No. 323230)

NOTE:

Specifications are subject to change without any obligaition on the part of the HITACHI.

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights continuously

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for

0.1 seconds. (off for 0.1 seconds)

Lights continuously

Before

charging

While

charging

Charging

complete

Charging

impossible

Charging

impossible

Blinks

(RED)

Lights

(RED)

Blinks

(RED)

Flickers

(RED)

Lights

(GREEN)

Malfunction in the battery

or the charger.

The battery temperature

is high, making

recharging impossible.

Indications of the lamps

Rechargeable batteries Temperatures at which the battery can be recharged

Ni-Cd type batteries 23°F – 140°F (–5°C – 60°C)

Ni-MH type batteries 32°F – 113°F (

0°C – 45°C)

(2) Regarding the temperature of the rechargeable battery.

The temperatures for rechargeable batteries are as shown in the table below, and batteries that have become

hot should be cooled for a while before being recharged.

Table 3 Recharging of batteries that have become hot

NOTE:

The charging time may vary according to temperature and power source voltage.

4. Disconnect battery charger from the receptacle

CAUTION:

●

Do not pull the plug out of the receptacle by pulling on the cord.

Make sure to grasp the plug when removing from receptacle to avoid damaging cord.

5. Remove the battery from the battery charger

Supporting the battery charger with hand, pull out the battery from the battery charger.

CAUTION:

●

When the battery charger has been continuously used, the battery charger will be heated, thus constituting

the cause of the failures. Once the charging has been completed, give 15 minutes rest until the next charging.

●

If the battery is recharged when it is warm due to battery use or exposure to sunlight, the pilot lamp may

light in green.

The battery will not be recharged. In such a case, let the battery cool before charging.

⟨UC18YG⟩

1. Connect the charger power cord to the receptacle

Connecting the power cord will turn on the charger.

2. Insert the battery into the charger

Insert the battery into the battery charger. Make sure it contacts the bottom of the battery charger (the pilot

lamp lights up).

CAUTION:

If the pilot lamp does not light up, pull out the power cord from the receptacle and check the battery

mounting condition.

About 60 minutes is required to fully charge the battery at a temperature of about 20°C. The pilot lamp goes off

to indicate that the battery is fully charged.

CAUTION:

If the battery is heated due to direct sunlight, etc., just after operation, the charger pilot lamp may not light

up. At that time, cool the battery first, then start charging.

3. Disconnect the charger power cord from the receptacle

4. Hold the charger tight and pull out the battery

Regarding electric discharge in case of new batteries, etc.

As the internal chemical substance of new batteries and batteries that have not been used for an extended period

is not activated, the electric discharge might be low when using them the first and second time. This is a temporary

phenomenon, and normal time required for recharging will be restored by recharging the batteries 2 – 3 times.

How to make the batteries perform longer

(1) Recharge the batteries before they become completely exhausted.

When you feel that the power of the tool becomes weaker, stop using the tool and recharge its battery. If you continue

to use the tool and exhaust the electric current, the battery may be damaged and its life will become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after use. If such a battery is recharged immediately after use,

its internal chemical substance will deteriorate, and the battery life will be shortened. Leave the battery and

recharge it after it has cooled for a while.

OPERATION

1. Using the light equipped hook

CAUTION:

●

Do not attach the tip tool to the tool main unit when carrying the tool main unit with the light equipped hook

suspended from a waist belt.

Such action could result in injury.

The light equipped hook has the following two functions:

䡬

It can be used as a hook for suspending from a waist belt when required by the nature of the work.

䡬

It can be used as an auxiliary light for such operations as tightening screws in a dark place.

1.1 Using the hook

The hook can be installed on the right or left side and the angle can be adjusted in 5 steps between 0° and 80°.

(1) Operating the hook

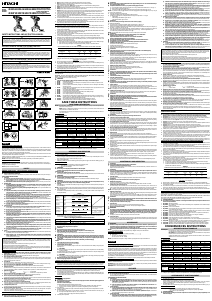

(a) Pull out the hook

E

toward you in the direction of arrow (A) and turn in the direction of arrow (B). (Fig. 5)

(b) The angle can be adjusted in 5 steps (0°, 20°, 40°, 60°, 80°).

Adjust the angle of the hook

E

to the desired position for use.

(2) Switching the hook position

ASSEMBLY AND OPERATION

REMOVAL AND INSTALLATION METHOD OF BATTERY

䡬

How to install the battery

Align the battery with the groove in tool handle and slip it into place.

Always insert

4

it all the way until it locks in place with a little click. If not, it may accidentally fall out of the

tool, causing injury to you or someone around you. (Fig. 1)

䡬

How to remove the battery

Withdraw

5

battery from the tool handle

3

while pressing the latch

2

on the side of the battery

1

. (Fig. 1)

CHARGING METHOD

NOTE:

Before plugging into the receptacle, make sure the following points.

䡬

The power source voltage is stated on the nameplate.

䡬

The cord is not damaged.

WARNING:

Do not charge at voltage higher than indicated on the nameplate.

If charged at voltage higher than indicated on the nameplate, the charger will burn up.

⟨

UC14YFA, UC24YFA

⟩

1. Insert the plug of battery charger into the receptacle

When the plug of battery charger has been inserted into the receptacle, pilot lamp will blink in red. (At 1-second intervals)

WARNING:

Do not use the electrical cord if damaged. Have it repaired immediately.

2. Insert the battery to the battery charger

Insert the battery into the battery charger. Make sure it contacts the bottom of the battery charger.

CAUTION:

●

If the batteries are inserted in the reverse direction, not only recharging will become impossible, but it may

also cause problems in the charger such as a deformed recharging terminal.

3. Charging

When the battery is connected to the battery charger, charging will commence and the pilot lamp will light in

red. (See Table 2)

NOTE:

If the pilot lamp flickers in red, pull out the plug from the receptacle and check if the battery is properly mounted.

When the battery is fully charged, the pilot lamp will blink in red slowly. (At 1-second intervals) (See Table 2)

(1) Pilot lamp indication

The indications of the pilot lamp will be as shown in Table 2, according to the condition of the charger or the

rechargeable battery.

Table 2

CAUTION:

●

If the tool falls, there is a risk that malfunction and/or physical damage can occur. It is recommended that you

also use fall-preventing wires, etc.

●

Incomplete installation of the hook

E

may result in bodily injury when used.

(a) Securely hold the main unit and remove the screw using a slotted head screwdriver or a coin. (Fig. 6)

(b) Remove the hook and spring

F

. (Fig. 7)

(c) Install the hook

E

and spring

F

on the other side and securely fasten with screw. (Fig. 6)

NOTE:

Pay attention to the spring

F

orientation. Install the spring

F

with larger diameter

G

away from you. (Fig. 8)

1.2 Using as an auxiliary light

(1) Press the switch

H

to turn off the light.

If forgotten, the light will turn off automatically after 15 minutes.

(2) The direction of the light can be adjusted within the range of hook positions 1 – 5. (Fig. 9)

䡬

Lighting time

AAAA manganese batteries: approx. 15 hrs.

AAAA alkali batteries: approx. 30 hrs.

CAUTION:

●

Do not look directly into the light. Such actions could result in eye injury.

1.3 Replacing the batteries

(1) Loosen the hook screw

J

with a Phillips-head screwdriver (No. 1)

I

. (Fig. 10)

Remove the hook cover

L

by pushing in the direction of the arrow. (Fig. 11)

(2) Remove the old batteries and insert the new batteries. Align with the hook indications and position the plus (+)

and minus (–) terminals correctly. (Fig. 12)

(3) Align the indentation in the hook

E

main body with the protuberance of the hook cover

L

, press the hook

cover

L

in the direction opposite to that of the arrow

K

shown in Fig. 11 and then tighten the screw.

Use commercially available AAAA batteries (1.5 V)

O

.

NOTE:

Do not tighten the screw excessively. Such action could strip the screw threads.

CAUTION:

●

Failure to observe the following can result in battery leakage, rust or malfunction.

Position the plus (+) and minus (–) terminals correctly.

Replace both batteries at the same time. Do not mix old and new batteries.

Remove exhausted batteries from the hook immediately.

●

Do not discard batteries together with normal trash and do not throw batteries into fire.

●

Store batteries out of the reach of children.

●

Use batteries correctly in accordance with the battery specifications and indications.

2. Installing the bit (Impact driver)

Always follow the following procedure to install driver bit. (Fig. 2)

(1) Pull the guide sleeve

7

back.

(2) Insert the bit

9

into the hexagonal hole in the anvil

8

.

(3) Release the guide sleeve

7

and it returns to its original position.

CAUTION:

●

If the guide sleeve does not return to its original position, then the bit is not installed properly.

3. Removing the bit (Impact driver)

Please do the opposite point on the method of installing bit.

4. Selecting the socket matched to the bolt (Impact wrench)

Be sure to use a socket which is matched to the bolt to be tightened. Using an improper socket will not only

result in insufficient tightening but also in damage to the socket or nut.

A worn or deformed hex. or square-holed socket will not give an adequate tightness for fitting to the nut or

anvil, consequently resulting in loss of tightening torque.

Pay attention to wear of socket hole, and replace before further wear has developed.

5. Installing a socket (Impact wrench)

Align the plunger located in the square part of the anvil

B

with the hole in the hex. socket

0

. Then push the

plunger, and mount the hex. socket

0

on the anvil

B

. Check that the plunger is fully engaged in the hole.

When removing the socket

0

, reverse the sequence.

6. Retaining ring type (Impact wrench)

(1) Align the square portions of the socket and the anvil with each other.

(2) Make sure to firmly install the socket by pushing it all the way into the anvil.

(3) When removing the socket, pull it out of the anvil.

CAUTION:

●

Please use the designated attachments which are listed in the operations manual and Hitachi’s catalog.

Accidents or injuries could result from not doing so.

●

Make sure to firmly install the socket in the anvil. If the socket is not firmly installed it might come out and

cause injuries.

7. Confirm that the battery is mounted correctly

8. Check the rotational direction

The bit rotates clockwise (viewed from the rear side) by pushing the R-side of the push button

C

.

The L-side of the push button is pushed to turn the bit counterclockwise. (See Fig. 4)

CAUTION:

●

The push button can not be switched while the impact driver is turning. To switch the push button, stop the

impact driver, then set the push button.

9. Switch operation

䡬

When the trigger switch is depressed, the tool rotates. When the trigger is released, the tool stops.

䡬

The rotational speed can be controlled by varying the amount that the trigger switch is pulled. Speed is low

when the trigger switch is pulled slightly and increases as the trigger switch is pulled more.

NOTE:

A buzzing noise is produced when the motor is about to rotate; this is only a noise, not a machine failure.

10. Tightening and loosening screws

Install the bit that matches the screw, line up the bit in the grooves of the head of the screw, then tighten it.

Push the impact driver just enough to keep the bit fitting the head of the screw.

CAUTION:

●

Applying the impact driver for too long tightens the screw too much and can break it.

●

Tightening a screw with the impact driver at an angle to that screw can damage the head of the screw and the

proper force will not be transmitted to the screw.

Tighten with this impact driver lined up straight with the screw.

11. Tightening and loosening bolts

A hex. socket matching the bolt or nut must first be selected. Then mount the socket on the anvil, and grip the

nut to be tightened with the hex. socket. Holding the wrench in line with the bolt, press the power switch to

impact the nut for several seconds.

If the nut is only loosely fitted to the bolt, the bolt may turn with the nut, therefore mistaking proper tightening.

In this case, stop impact on the nut and hold the bolt head with a wrench before restarting impact, or manually

tighten the bolt and nut to prevent them slipping.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest the unit for 15 minutes or so when replacing the battery.

The temperature of the motor, switch, etc. will rise if the work is started again immediately after battery

replacement, eventually resulting in burnout.

CAUTION:

Do not touch the protector, as it gets very hot during continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which steplessly varies the rotation speed. Consequently, when the

switch trigger is pulled only slightly (low speed rotation) and the motor is stopped while continuously driving

in screws, the components of the electronic circuit parts may overheat and be damaged.

3. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according to the material and size of the screw, and the material

being screwed etc., so please use a tightening time suitable for the screw. In particular, if a long tightening time

is used in the case of screws smaller than 5/16” (8 mm), there is a danger of the screw breaking, so please

confirm the tightening time and the tightening torque beforehand.

4. Work at a tightening torque suitable for the bolt under impact

The optimum tightening torque for nuts or bolts differs with material and size of the nuts or bolts. An excessively

large tightening torque for a small bolt may stretch or break the bolt. The tightening torque increases in

proportionate to the operation time. Use the correct operating time for the bolt.

5. Holding the tool

Hold the impact wrench firmly with both hands. In this case hold the wrench in line with the bolt.

It is not necessary to push the wrench very hard. Hold the wrench with a force just sufficient to counteract the impact force.

6. Confirm the tightening torque

The following factors contribute to a reduction of the tightening torque. So confirm the actual tightening torque needed by

screwing up some bolts before the job with a hand torque wrench. Factors affecting the tightening torque are as follows.

(1) Voltage

When the discharge margin is reached, voltage decreases and tightening torque is lowered.

(2) Operating time

The tightening torque increases when the operating time increases. But the tightening torque does not increase

above a certain value even if the tool is driven for a long time.

(3) Diameter of bolt

The tightening torque differs with the diameter of the bolt. Generally a larger diameter bolt requires larger

tightening torque.

(4) Tightening conditions

The tightening torque differs according to the torque ratio, class, and length of bolts even when bolts with the same

size threads are used. The tightening torque also differs according to the condition of the surface of workpiece

through which the bolts are to be tightened. When the bolt and nut turn together, torque is greatly reduced.

(5) Using optional parts (Impact wrench)

The tightening torque is reduced a little when an extension bar, universal joint or a long socket is used.

(6) Clearance of the socket (Impact wrench)

A worn or deformed hex. or a square-holed socket will not give an adequate tightness to the fitting between

the nut or anvil, consequently resulting in loss of tightening torque.

Using an improper socket which does not match to the bolt will result in an insufficient tightening torque.

Français

INFORMATIONS IMPORTANTES DE SÉCURITÉ

Lire et comprendre toutes les précautions de sécurité, les avertissements et les instructions de fonctionnement

dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé proviennent d’un non respect

des règles ou précautions de base de sécurité. Un accident peut la plupart du temps être évité si l’on reconnaît une

situation de danger potentiel avant qu’elle ne se produise, et en observant les procédures de sécurité appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE” de ce mode d’emploi et

dans les sections qui contiennent les instructions de fonctionnement et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un endommagement de la machine

sont identifiés par AVERTISSEMENTS sur l’outil motorisé et dans ce mode d’emploi.

NE JAMAIS utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement recommandée par HITACHI.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont ignorées, pourraient entraîner

la mort ou de sérieuses blessures.

ATTENTION indique des situations dangereuses potentilles qui, si elles ne sont pas évitées, peuvent entraîner de

mineures et légères blessures ou endommager la machine.

REMARQUE met en relief des informations essentielles.

SECURITE

REGLES GENERALE DE SECURITE – POUR TOUS LES OUTILS FONCTIONNANT SUR BATTERIE

AVERTISSEMENT:

Lire et coxmprendre toutes les instructions.

Un non respect de toutes les instructions ci-dessous peut entraîner une électrocution, un incendie et/ou de

sérieuses blessures personnelles.

CONSERVER CES INSTRUCTIONS

1. Zone de travail

(1)

Garder la zone de travail propre et bien éclairée. Les établis mal rangés et les zones sombres invitent aux accidents.

(2) Ne pas utiliser les outils motorisés dans une atmosphère explosive, telle qu’en présence de liquides

inflammables, de gaz ou de poussières. Les outils motorisés créent des étincelles qui risquent d’enflammer

la poussière ou les vapeurs.

(3) Tenir les spectateurs, les enfants et les visiteurs éloignés, lors de l’utilisation de l’outil motorisé. Une

distraction peut faire perdre le contrôle de la machine.

2. Sécurité électrique

(1) Un outil motorisé à batterie avec batterie intégrée ou batterie séparée ne devra être rechargé qu’avec le

chargeur spécialement conçu pour la batterie. Un chargeur qui convient pour un type de batterie donné

peut présenter un risque de feu s’il est utilisé avec une autre batterie.

(2) Utiliser l’outil motorisé à batterie exclusivement avec la batterie spécialement conçue. L’utilisation de

toute autre batterie peut présenter un risque de feu.

3. Sécurité personnelle

(1)

Rester sur ses gardes, regarder ce que l’on fait et utiliser son sens commun lors de l’utilisation d’un outil motorisé.

Ne pas utiliser un outil en état de fatigue ou sous l’influence de drogues, d’alcool ou de médicaments. Un moment

d’inattention lors de l’utilisation de l’outil motorisé peut entraîner de sérieuses blessures personnelles.

(2) S’habiller correctement. Ne pas porter des vêtements larges ou des bijoux. Attacher les cheveux longs.

Tenir ses cheveux, vêtements et ses gants éloignés des parties mobiles. Les vêtements larges, les bijoux

et les cheveux longs peuvent se prendre dans les parties mobiles.

(3) Eviter tout démarrage accidentel. S’assurer que le l’interrupteur d’alimentation est sur la position d’arrêt

avant de brancher la machine. Transporter l’appareil avec les doigts sur l’interrupteur d’alimentation ou

brancher un outil avec l’interrupteur sur la position marche invite aux accidents.

(4) Retirer les clefs d’ajustement ou les commutateurs avant de mettre l’outil sous tension. Une clef qui est

laissée attachée à une partie tournante de l’outil peut provoquer une blessure personnelle.

(5) Ne pas trop présumer de ses forces. Garder en permanence une position et un équilibre correct. Une

position et un équilibre correct permettent un meilleur contrôle de l’outil dans des situations inattendues.

(6) Utiliser un équipement de sécurité. Toujours porter des lunettes de protection. Un masque à poussière,

des chaussures de sécurité antidérapantes, un chapeau dur et des bouchons d’oreille doivent être utilisés

dans les conditions appropriées.

4. Utilisation de l’outil et entretien

(1) Utiliser un étau ou toutes autres façons de fixer et maintenir la pièce à usiner sur une plate-forme stable.

Tenir la pièce avec la main ou contre son corps est instable et peut conduire à une perte de contrôle de l’outil.

(2) Ne pas forcer sur l’outil. Utiliser l’outil correct pour l’application souhaitée. L’outil correct réalisera un

meilleur et plus sûr travail dans le domaine pour lequel il a été conçu.

(3) Ne pas utiliser un outil s’il ne se met pas sous ou hors tension avec un interrupteur. Un outil qui ne peut

pas être commandé avec un interrupteur est dangereux et doit être réparé.

(4) Débrancher la batterie de l’outil ou mettre l’interrupteur sur la position verrouillée ou éteinte avant

d’effectuer un réglage, de remplacer un accessoire ou de ranger l’outil. Ces mesures de sécurité préventives

réduiront les risques de déclenchement accidentel de l‘outil.

(5) Ranger les outils inutilisés hors de la portée des enfants et des autres personnes inexpérimentées. Les

outils sont dangereux dans les mains de personnes inexpérimentées.

(6) Lorsqu’on ne se sert pas de la batterie, l’éloigner des objets métalliques, par exemple trombones, pièces

de monnaie, clous, vis, ou petits objets métalliques qui peuvent créer une connexion entre deux bornes.

Le fait de court-circuiter les bornes entre elles peut provoquer des étincelles, des brulûres ou un feu.

(7) Conserver les outils avec soin. Garder les outils de coupe aiguisés et propres. Des outils bien entretenus,

avec des lames coupantes aiguisées risquent moins de se gripper et sont plus faciles à contrôler.

(8) Vérifier les défauts d’alignement ou grippage des parties mobiles, les ruptures des pièces et toutes les

autres conditions qui peuvent affecter le fonctionnement des outils. En cas de dommage, faire réparer

l’outil avant de l’utiliser. Beaucoup d’accidents sont causés par des outils mal entretenus.

(9) Utiliser uniquement les accessoires recommandés par le fabricant pour le modèle utilisé. Des accessoires

qui peuvent convenir à un outil, peuvent devenir dangereux lorsqu’ils sont utilisés avec un autre outil.

5. Réparation

(1) La réparation de l’outil ne doit être réalisée uniquement par un réparateur qualifié. Une réparation ou un

entretien réalisé par un personnel non qualifié peut entraîner des risques de blessures.

(2) Lors de la réparation d’un outil, utiliser uniquement des pièces de rechange identiques. Suivre les

instructions de la section d’entretien de ce mode d’emploi. L’utilisation de pièces non autorisées ou un

non respect des instructions d’entretien peut créer un risque d’électrocution ou de blessures.

AVERTISSEMENT:

La poussière résultant d'un ponçage, d'un sciage, d'un meulage, d'un perçage ou de toute autre activité de construction

renferme des produits chimiques qui sont connus par l'Etat de Californie pour causer des cancers, des défauts de

naissance et autres anomalies de reproduction. Nous énumérons ci-dessus certains de ces produits chimiques :

●

Plomb des peintres à base de plomb,

●

Silice cristalline des briques et du ciment et autres matériaux de maçonnerie, et

●

Arsenic et chrome du bois d'oeuvre traité chimiquement.

Le risque d'exposition à ces substances varie en fonction de la fréquence d'exécution de ce genre de travail. Pour

réduire l'exposition à ces produits chimiques, travailler dans un lieu bien ventilé, et porter un équipement de protection

agréé, par exemple un masque anti-poussière spécialement conçu pour filter les particules microscopiques.

REGLES DE SECURITE SPECIFIQUES

1. Tenir les outils par les surfaces de grippage lors de la réalisation d’opération où l’outil de coupe risque d’entrer

en contact avec des câbles cachés. Un contact avec un fil “sous tension” mettra les parties métalliques de

l’outil “sous tension” et électrocutera l’utilisateur.

2. Ne jamais toucher les parties mobiles.

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des parties mobiles de l’outil.

3. Ne jamais utiliser l’outil sans que tous les dispositifs de sécurité ne soient en place.

Ne jamais faire fonctionner cet outil sans que tous les dispositifs et caractéristiques de sécurité ne soient en

place et en état de fonctionnement. Si un entretien ou une réparation nécessite le retrait d’un dispositif ou

d’une caractéristique de sécurité, s’assurer de bien remettre en place le dispositif ou la caractéristique de

sécurité avant de recommencer à utiliser l’outil.

4. Utiliser l’outil correct

Ne pas forcer sur un petit outil ou accessoire pour faire le travail d’un outil de grande puissance.

Ne pas utiliser un outil pour un usage pour lequel il n’a pas été prévu : par exemple, ne pas utiliser une scie

circulaire pour couper des branches d’arbre ou des bûches.

5. Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées.

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées dans le mode d’emploi.

6. Manipuler l’outil correctement.

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou lancer l’outil. Ne jamais

permettre que l’outil soit utilisé par des enfants, des personnes non familiarisées avec son fonctionnement ou

un personnel non autorisé.

7. Définitions pour les symboles

V ................. volts n

o

........... no vitesse à vide

---

— ................ courant continu ---/min .... rotations ou mouvements de va-et-vient par minute

8. Maintenir toutes les vis, tous les boulons et les couvercles fermement en place.

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier leurs conditions périodiquement.

9. Ne pas utiliser les outils motorisés si le revêtement de plastique ou la poignée est fendu.

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De tels outils ne doivent pas

être utilisés avant d’être réparé.

10. Les lames et les accessoires doivent être fermement montés sur l’outil.

Eviter les blessures potentielles personnelles et aux autres. Les lames, les instruments de coupe et les accessoires

qui ont été montés sur l’outil doivent être fixés et serrés fermement.

11. Ne jamais utiliser un outil défectueux ou qui fonctionne anormalement.

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela paraît défectueux,

arrêter de l’utiliser immédiatement et le faire réparer par un centre de service Hitachi autorisé.

12. Manipuler l’outil motorisé avec précaution.

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être déformé, fendu ou endommagé.

13. Ne pas essuyer les parties en plastique avec du solvant.

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et l’alcool peuvent

endommager et fissurer les parties en plastique. Ne pas les essuyer avec de tels solvants.

Essuyer les parties en plastique avec un chiffon doux légèrement imbibé d’une solution d’eau savonneuse et

sécher minutieusement.

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR L’UTILISATION DU CLÉ À CHOC / VISSEUSE

À PERCUSSION À BATTERIE

AVERTISSEMENT:

Une utilisation incorrecte ou sans sécurité du tournevis à percussion sans fil risque d'entraîner la mort ou des

blessures graves. Pour éviter ces risques, observer les consignes de sécurité élémentaires suivantes:

1. Ne jamais utiliser ce manche de cet outil pour une application autre que celles décrites dans le manuel.

2. Ne jamais mettre les mains ni aucune autre partie du corps près du foret ni du mandrin pendant le

fonctionnement. Tenir le tournevis à percussion uniquement par son manche.

3. Lors d'un travail en hauteur, toujours s'assurer qu'il n'y a personne dessous avant de commencer.

4. Toujours porter des protections pour les yeux et les oreilles pendant le travail.

5. Toujours insérer le foret à fond. Un foret lâche serait dangereux car il pourrait se détacher pendant le travail.

(Visseuse à percussion)

6. Toujours utiliser un foret correspondant à la taille du tournevis. (Visseuse à percussion)

7. Toujours disposer la vis que l'on veut enfoncer et le tournevis à percussion en ligne droite. Avec ce tournevis

à percussion, le fait de travailler à angle par rapport à la vis risque d'endommager la tête de la vis et ne

permettra pas d'obtenir le couple de serrage spécifié. (Visseuse à percussion)

8. Vérifier qu’il n’y a pas de fissure sur la douille. (Clé à choc)

9. Fixer la douille hexagonale solidement sur le piton. Si la douille hexagonale n’est pas fixée assez solidement,

elle risque de tomber et de provoquer un accident. Pour l’accessoire de douille hexagonale, voir “UTILISATION”.

10. Vérifier le couple de serrage à l’aide d’une clé dynamométrique avant l’utilisation, de façon à s’assurer que le

couple de serrage sera correct. (Clé à choc)

11. Si l’on utilise un joint universel, ne pas faire fonctionner l’outil à vide. Cela serait dangereux. Si la section de la

douille tourne autour du joint, cela risque de provoquer des blessures aux mains et sur le corps, ou sous l’effet

des vibrations intenses qui en résulteraient, l’utilisateur risque de laisser tomber l’outil. (Clé à choc)

12. Veiller à ce qu’aucun corps étranger ne bloque les orifices situés des deux côtés de la poignée. Par ailleurs, ne

pas boucher les orifices avec du ruban adhésif. Ces orifices remplissent une fonction importante. (Clé à choc)

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR LE CHARGEUR DE BATTERIE

1. Ce manuel renferme des consignes de sécurité et d’utilisation importantes pour le chargeur de batterie modèle

UC14YFA ou UC24YFA ou UC18YG.

2. Avant d’utiliser le chargeur de batterie, lire toutes les étiquettes d’instruction et de précaution apposées sur (1)

le chargeur de batterie, (2) la batterie, et (3) le produit utilisant la batterie.

3. Pour réduire tout risque de blessure, ne recharger que les batteries rechargeables HITACHI utilisées dans le

modèle series EB7, EB9, EB12, EB14 et EB18. Les autres types de batterie pourraient exploser et provoquer des

blessures ou des dommages.

4. Ne pas exposer le chargeur à la pluie ni à la neige.

5. L’utilisation d’un accessoire non recommandé ou non vendu par le fabricant du chargeur de batterie risque de

provoquer un feu, une décharge électrique ou des blessures.

6. Pour réduire tout risque de dommage de la fiche et du cordon électrique, débrancher le cordon du chargeur en

tirant sur la fiche.

7. Vérifier que le cordon est placé de façon que personne ne puisse marcher dessus, se prendre les pieds dedans,

ni l’endommager ou le soumettre à des contraintes.

8. Ne pas utiliser de cordon de rallonge si cela n’est pas absolument nécessaire. L’utilisation d’un cordon de

rallonge incorrect pourrait entraîner un feu ou une décharge électrique.

Si l’on doit utiliser un cordon de rallonge, s’assurer que:

a. Les broches de la rallonge ont les mêmes numéro, taille et forme que celles de la fiche du chargeur;

b. Le cordon de rallonge est correctement raccordé et en bon état électrique;

c. Le calibre du fil doit être au moins suffisant pour l’intensité nominale CA (ampères) du chargeur de batterie

spécifiées dans le tableau ci-dessous.

Tableau 1

CALIBRE MINIMUM RECOMMANDÉ POUR LES CORDONS DE RALLONGE DES CHARGEURS DE BATTERIE

Intensité nominale d’entrée CA (ampères)* Calibre du cordon

Egal ou mais non Longueur de cordon en pieds (mètres)

supérieur à inférieur à 25 (7.5) 50 (15) 100 (30) 150 (45)

0 2 18 18 18 16

2 3 18 18 16 14

3 4 18 18 16 14

*Si l’intensité nominale d’entrée du chargeur de batterie est donnée en watts et non en ampères, calculer la

capacité en ampères correspondante en divisant la capacité en ampères par la capacité de tension, par exemple:

1,250 watts

125 volts

=

10 ampères

9. Ne pas utiliser le chargeur si son cordon ou sa fiche sont endommagés – Le remplacer immédiatement.

10. Ne pas utiliser le chargeur s’il a reçu un coup, s’il est tombé ou endommagé de toute autre manière. L’apporter

à un réparateur qualifié.

11.

Ne pas démonter le chargeur ni le produit qui reçoit la batterie; si un entretien ou des réparations sont nécessaires, les

apporter à un réparateur qualifié. Un remontage incorrect pourrait provoquer une décharge électrique ou un feu.

12. Pour réduire tout risque de décharge électrique, débrancher le chargeur de la prise secteur avant tout entretien

ou nettoyage. Il ne suffit pas de sortir la batterie.

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR L’UTILISATION DE LA BATTERIE ET DU CHARGEUR DE BATTERIE

Pour pouvoir utiliser la clé à choc à batterie, il faudra recharger la batterie. Avant d’utiliser le chargeur de batterie

modèle UC14YFA ou UC24YFA ou UC18YG, bien lire attentivement toutes les consignes et les avertissements signalés

sur le chargeur, sur la batterie ou dans ce manuel.

BIEN NOTER: UTILISER EXCLUSIVEMENT DES BATTERIES HITACHI DES SERIES EB7, EB9, EB12, EB14 ET EB18.

LES AUTRES TYPES DE BATTERIE POURRAIENT EXPLOSER OU PROVOQUER DES BLESSURES!

Pour éviter tout risque de blessure, observer les consignes suivantes:

AVERTISSEMENT:

Une utilisation incorrecte de la batterie ou du chargeur de batterie risque de provoquer des blessures. Pour

éviter tout risque de blessure:

1. NE JAMAIS démonter la batterie.

2. NE JAMAIS jeter la batterie au feu, même si elle est endommagée ou complètement usée. La batterie risque

d’exploser au feu.

3. NE JAMAIS court-circuiter la batterie.

4. NE JAMAIS insérer d’objets dans les ouïes d’aération du chargeur. Il pourrait en résulter un choc électrique

ou des dommages du chargeur.

5. NE JAMAIS effectuer la recharge à l’extérieur. Eloigner la batterie des rayons directs du soleil et utiliser

exclusivement dans des endroits à faible humidité et bien aérés.

6. NE JAMAIS effectuer la recharge si la température est inférieure à 32°F (0°C) ou supérieure à 104°F (40°C).

7. NE JAMAIS raccorder deux chargeurs de batterie ensemble.

8. NE JAMAIS insérer de corps étrangers dans l’orifice de la batterie ou du chargeur de batterie.

9. NE JAMAIS utiliser de transformateur-élévateur pour la recharge.

10. NE JAMAIS utiliser de générateur de moteur ni d’alimentation CC pour la recharge.

11. NE JAMAIS ranger la batterie ni le chargeur de batterie dans un lieu où la température peut atteindre ou

dépasser 104°F (40°C).

12. TOUJOURS alimenter le chargeur sur une prise secteur domestique standard (120 volts). L’utilisation du

chargeur à une autre tension peut entraîner une surchauffe et endommager le chargeur.

13. TOUJOURS attendre au moins 15 minutes entre deux recharges pour éviter toute surchauffe du chargeur.

14. TOUJOURS débrancher le cordon d’alimentation de la prise secteur lorsqu’on ne se sert pas du chargeur.

CONSERVER CES INSTRUCTIONS

DESCRIPTION FONCTIONNELLE

REMARQUE :

Les informations contenues dans ce mode d’emploi sont conçues pour assister l’utilisateur dans

une utilisation sans danger et un entretien de l’outil motorisé.

NE JAMAIS utiliser ni entreprendre une révision de l’outil sans avoir d’abord lu et compris toutes

les instructions de sécurité contenues dans ce manuel.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des accessoires

différents de ceux de l’outil motorisé utilisé.

SPECIFICATIONS

1. Visseuse à percussion à batterie

Modèle WH9DMR WH12DMR WH14DMR WH18DMR

Tension 9.6 V 12 V 14.4 V 18 V

Vitesse sans charge 0 – 2600 / min

Capacité (boulon ordinaire)

M5 – M12 M6 – M14

Couple de serrage 930 in-lbs 1,150 in-lbs 1,240 in-lbs 1,330 in-lbs

(Maximum) (105 N·m) (130 N·m) (140 N·m) (150 N·m)

Poids 3.1 lbs. (1.4 kg) 3.5 lbs. (1.6 kg) 3.9 lbs. (1.8 kg) 4.4 lbs. (2.0 kg)

Modèle UC14YFA UC24YFA UC18YG

Tension de chargement

7.2 – 14.4 V 7.2 – 24 V 7.2 – 18 V

Durée de

2.0 Ah 50 min. 50 min. 50 min.

2.6 Ah 65 min. 65 min. x

chargement

3.0 Ah 70 min. 70 min. x

Poids 1.3 lbs. (0.6 kg) 1.3 lbs. (0.6 kg) 0.7 lbs. (0.3 kg)

Modèle WR9DMR WR12DMR WR14DMR WR18DMR

Tension 9.6 V 12 V 14.4 V 18 V

Vitesse sans charge 0 – 2600 / min

Capacité (Boulon ordinaire)

M6 – M14 M10 – M16

Couple de serrage 1,020 in-lbs 1,420 in-lbs 1,720 in-lbs 1,950 in-lbs

(Maximum) (115 N·m) (160 N·m) (195 N·m) (220 N·m)

Poids 3.1 lbs. (1.4 kg) 3.5 lbs. (1.6 kg) 3.9 lbs. (1.8 kg) 4.4 lbs. (2.0 kg)

2. Clé à choc batterie

3. Chargeur de batterie

Les durées de chargement sont approximatives. La durée réelle de chargement peut varier.

“x” indique que la batterie n’est pas compatible avec ce chargeur spécifique.

ASSEMBLAGE ET FONCTIONNEMENT

MÉTHODE DE RETRAIT ET D’INSTALLATION DE LA BATTERIE

䡬

Installation de la batterie

Aligner la batterie sur la fente de la poignée de l’outil et la glisser à l’intérieur.

Toujours insérer

4

la batterie à fond, jusqu’à ce qu’elle se bloque avec un petit déclic. Sinon, elle risque de

tomber accidentellement de l’outil et de blesser l’opérateur ou d’autres personnes alentour. (Fig. 1)

䡬

Installation de la batterie

Sortir la

5

batterie de la poignée de l’outil

3

tout en appuyant sur les taquet

2

de chaque côté de la batterie

1

.

(Fig. 1)

MÉTHODE DE RECHARGE

REMARQUE:

Avant de brancher le chargeur dans la prise, vérifier les points suivants.

䡬

La tension de la source d’alimentation est indiquée sur la plaque signalétique.

䡬

Le cordon n’est pas endommagé.

AVERTISSEMENT:

Ne pas effectuer de recharge à une tension supérieure à la tension indiquée sur la plaque signalétique. Cela

brûlerait le chargeur.

F

C

DD

6

7

9

8

A

0

B

E

G

H

J

E

I

K

E

M

L

N

O

N

M

,

.

,

.

P

3mm

11.5mm

Q

R

S

5

5

4

3

2

4

3

1

2

1

Code No. C99137461

Join the conversation about this product

Here you can share what you think about the Hitachi WH 9DMR Impact Wrench. If you have a question, first carefully read the manual. Requesting a manual can be done by using our contact form.